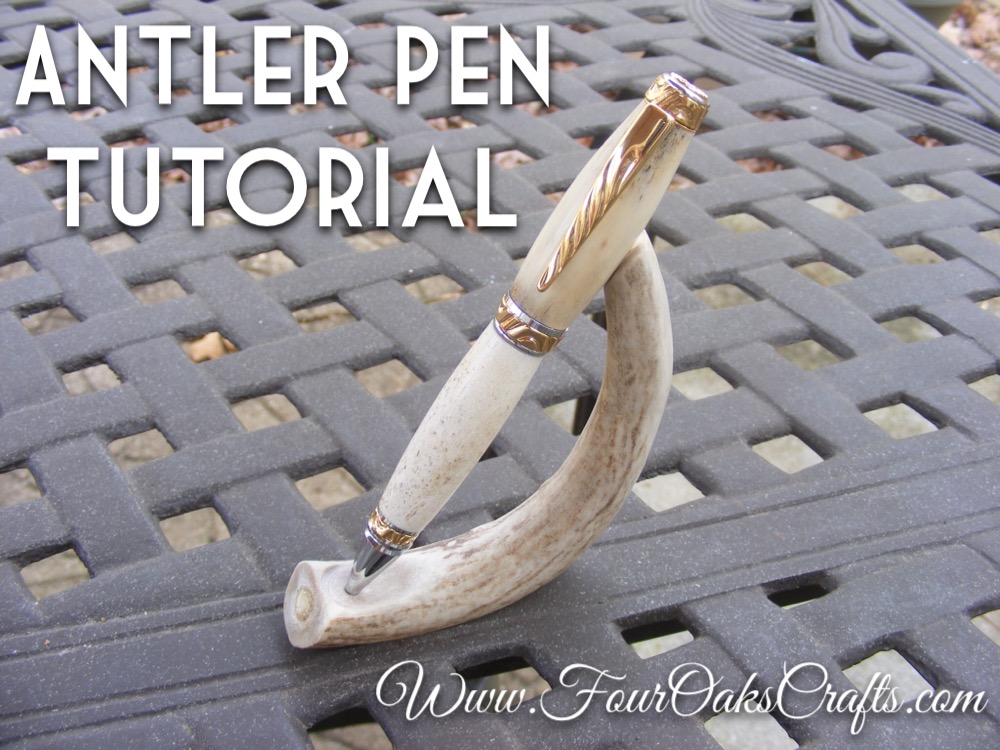

The deer antler pen continues to be one of my favorite pen making projects. Even after 10 years of doing this, pen turning continues to be an exciting hobby for me. There are so many variations of pens to make. So many materials out there to choose from. In 12 steps, this tutorial will show you how to make a deer antler pen.

Are you ready for a fun challenge? Let’s get things turning!

Let me state up front that turning deer antler is not very different from turning wood. And I’m assuming you have some previous experience turning wood on a lathe. Antler comes with its own set of challenges, but also provides s a beautiful and unique material for pens. I will be using antler from the whitetail deer, but you can also acquire antler from other deer species.

I enjoy finding antler in the woods. The male whitetail deer sheds his antlers during the winter months, and grows a new set each year. You can also buy antler materials from the pen supply companies. Or check on EBay or Etsy.

YouTube — Faith, Hope, Love Pen Kit

You can watch the YouTube video below where I make another antler pen kit called the Faith, Hope, Love pen kit. The rest of this post covers the other kit called the cigar pen kit.

Cigar Pen Kit Antler Tutorial

For my written tutorial, I’m using the Ultra Cigar Pen kit from Woodcraft. PSI and Woodcraft also make other variations of the Cigar Pen, but I love how the Ultra Cigar Pen looks. It’s decorative, but doesn’t over do it. As you’ve probably guessed, it’s called a cigar pen because of the shape. If you like bigger, heavier pens, you will enjoy this pen. And it tends to be a favorite among men. And the antler will certainly be a favorite for outdoorsman or nature lovers.

Materials, supplies, and tools needed:

Ultra Cigar Pen Kit

Cigar Pen Bushings

10 mm drill bit

CA clue (medium and thin)

Sandpaper/Micro Mesh

Barrel Trimmer

Wood lathe and pen mandrel

Electric drill or drill press

Safety gear

In the steps and pictures below, I will give you the information and steps to make your first deer antler cigar pen.

Step 1 – Select your antlers blanks. Pick out sections of antler that are as straight as possible. For the Cigar Kit, I’d recommend antler pieces about 3/4 inch to 1 inch in diameter. Look through pen supply catalogs and you will see pictures of various pens made from antler. The catalog pictures or Google images give you a great idea of what looks good and what doesn’t. Since this kit requires two different antler blanks, try to get the blanks from the same set of antlers if possible. This may help cut down on drastic color variations.

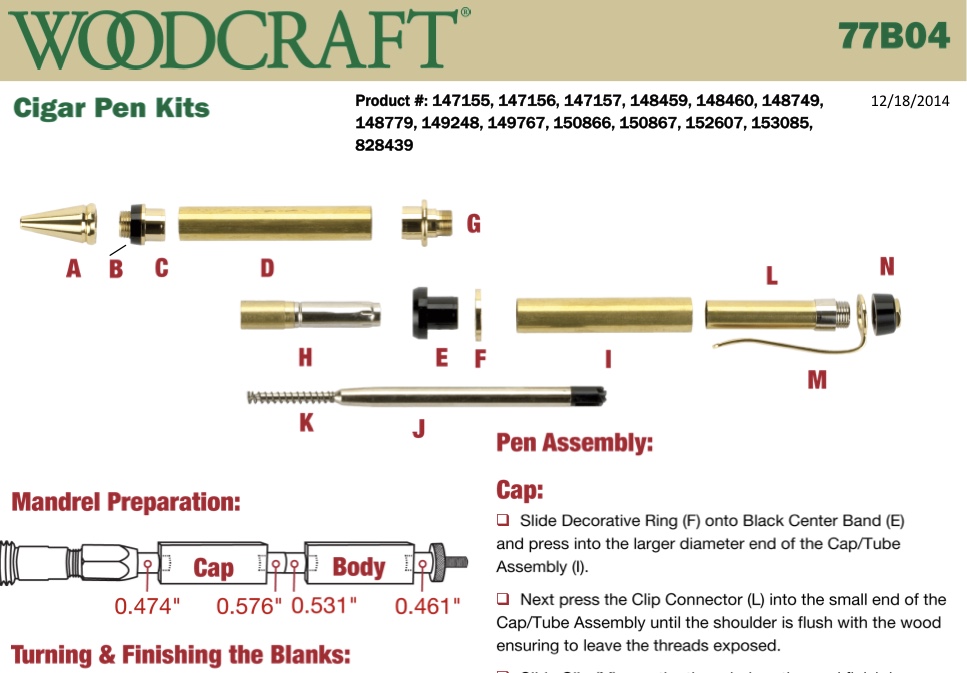

Step 2 – Pull out the contents of the Cigar Pen Kit and make sure you have all the pieces: pen tubes, ink refill, cap and clip, twist mechanism, center band, and the tip. NOTE—each kit should come with a set of printed instructions (or you can download from internet). Make sure you carefullly read and follow those instructions.

The pen parts come in different colors and styles of platings. Some platings like Titanium or Platinum are very durable and resist wear and tear much longer. Match your antler color with the plating. Again, I recommend looking at finished pens in catalogs or magazines to get ideas. Antler colors will vary also. You could see white colors, cream colors, or gray colors — or a combination of all three. Each antler is unique.

Some people like to leave the “bark” on the antler. To do that you may have to make the body of the pen a wider diameter or you may have to drill the pen tube hole slightly off center.

Step 3 – Using the Cigar Pen tubes as your guide, mark the areas on the antler sections, which will get you ready for step 4—cutting with the bandsaw or hacksaw. Leave about 1/8 to 1/4 inch extra length on each end of each blank section. DO NOT cut the antler sections exactly to the tube length. Note that one tube is shorter than the other, so use BOTH tubes to measure each section accordingly, and write “S” on the shorter piece, and “L” on the longer one. This will help you keep them straight. And remember — it would be ideal to get both antler blanks from the same antler piece, but if you can’t don’t sweat over it.

Step 4 – Cut the antler blanks on the previously made marks. If you don’t feel comfortable cutting antler on the bandsaw, then use a hacksaw. Some times you don’t have room to cut sections of antler on a bandsaw or it may not easily feed through the bandsaw. Take a piece of masking tape and place a piece evenly around the antler to act as a guide. Work the hacksaw blade around the antler, staying on the edge of the tape.

Step 5 – Using a 10 mm drill bit, drill through the center point of the upper antler section. Next, drill the lower antler section. It can be a challenge to find the center of an antler since they have an irregular shape or contour. I like to square up my antler blanks with the disc sander first. That way I can easily fit them in my centering vise for the drill press. Take time with this step since you only get one shot with this one blank. Here’s a tip — It’s good to have extra Cigar Blank tubes (and deer antler) on hand if you have to start over.

Don’t drill too fast and don’t overheat the bit and antler. Go into the antler a little ways and then pull out to remove waste. Clean the drill bit periodically if needed. Following this process helps ensure you get a clean hole for the pen tubes and minimizes the risk of blowing out an antler blank or causing cracks.

In the picture above, you can see I’m using a drill press and a vise made specially for pen blanks. But you can use other generic type vises. You can even use a hand drill if you want. Just make sure you’ve safely secured the antler blanks.

Also, don’t forget to wear your safety glasses and respirator during all drilling and cutting operations.

Step 6 – Next, use CA glue (medium) to glue the pen tubes in place. Before you glue, make sure to take some sand paper and scuff the tube’s outside surface. Each tube should be recessed within the blank so extra antler is left on each end (preferably 1/8 to 1/4 inch) for the barrel trimmer (step 7).

CA glue sets really fast so don’t delay in getting the tubes positioned and set in the blank. Some people like to use an expoxy instead of CA. I like to apply the CA glue to the top of the tube as I twirl and push the tube inside the antler blank. Wear nitrile gloves so you don’t get glue on your fingers.

Step 7 – After the glue has set (I usually like to wait an hour) you can then take the barrel trimmer and trim the antler down to the pen tubes. Make sure you have a sharp barrel trimmer. For this step, I like to use a portable drill. Go light and be careful not to cut deeply into your pen tubes. Simply trim until you start to see the brass from the tube, then stop. The trimming process will ensure that the ends of the blanks are square or flush with the pen tubes. This will help everything fit properly when we later assemble the pen.

Step 8 – Now you can mount the blanks to the turning mandrel. I will be using my mandrel saver as shown in the top photo. Place the Cigar bushings on both ends and the center, between the blanks. The bushings control the dimensions of the pen’s body. This kit has 3 different size bushings. The middle bushing is a step bushing. Make sure you have the correct bushings positioned accordingly with the short and long blanks. Refer to the pen instructions to see the bushing layout diagram. Study this diagram very carefully.

Make sure you leave room between blanks and around the ends so you can easily maneuver the turning tools.

Step 9 – Make sure your turning gouge is sharp and begin turning the blanks into cylinders. For antler material, I normally stick with a spindle gouge. Make sure your tail stock is locked and has firm pressure on the pen mandrel. Only not too tight. Setting the tail stock too tight could make the mandrel bow.

Put on your face shield and turn on the lathe. Lathe speed should be about 2000 to 3000 RPM (revolutions per minute). Make sure the gouge is firmly sitting on the tool rest and you have positive control of the tool. Next, ease the tool into the antler. Remember that antler is hard and you’re starting with an irregular shape. So gradually cut away on the antler. It will eventually get easier as the antler becomes a cylinder. Remember not to turn all the way down to the bushings. Final shaping will be done in the sanding step.

Stop periodically and examine the antler. Antler can be very porous so I like to stop the lathe and apply some thin CA glue which absorbs easily into the pours. Once that dries, follow with some medium CA glue. You can use accelerant to speed up the drying time.

Note—if you’ve never used a lathe before, you might want to get some training and/or practice on wood blanks first just to get the feel and understand the technique. I assure you that this is very easy to master.

Step 10 – Remove the tool rest, and now begin sanding the blanks with 120 grit sandpaper. Continue using the 120 grit sandpaper until you’re almost flush with the bushing. Also, check to see that you’ve removed excess CA glue from the previous step. If the antler still seems very porous, apply the thin and medium CA glue as done previously. Let that dry, and then sand again with 120 grit.

Next, move from 120 grit, to 220 grit. Use the 220 grit to make the antler flush with the bushings. Next, go to the 320 grit sandpaper, and then 500 grit. I take some additional steps and use Micro Mesh sanding cloths (1500 grit to 20,000 grit). The micro mesh is optional, but it does make the antler polish well. You can do your sanding wet or dry. I’ve done it both ways. Antler will polish to a nice glossy look, which is one thing I love about antler.

Step 11 – Apply a finish of choice. Some people like to apply a CA finish to antler, but I don’t suggest doing that if you are a beginner. You might experiment with using some of the polishes used on acrylic pens. But to be honest, I don’t put any finish on my antler pens. Antler polishes very nicely during the sanding process. If you do decide to apply a polish, read the instructions on the container, and remember to wear your safety glasses. Also, don’t use an applicator that will stick to the blank and get caught up in the lathe. Most people generally use paper towels as the applicator.

Step 12 – Assemble the antler pen. Although I have a pen press, I like to use my bench-mounted vise to press the pen parts into place. Pull out your assembly diagram which is found on the Cigar Pen Kit instructions. Remember that you have 2 different size sections for this pen. The Pen diagram will tell you exactly which pen part goes where and the order of assembly.

Follow the cigar pen kit instructions and first assemble the cap section of the pen which is the shorter piece. just remember that the clip and cap/tube assembly will press into the SMALLER diameter side of the “Cap” (shorter) section.

Next, follow the kit instructions and assemble the body section which is the longer section of the pen. Just remember that your nib (tip) and nib adapter will go into the SMALLER diameter of this “Body” or long section of the pen.

Some tips for assembly:

Take your time and go slow.

Follow assembly instructions exactly.

Make sure parts are pressing into the pen tubes straight.

I like to rotate and reposition as I press.

Don’t apply excessive pressure.

When assembly is complete, test out the twist mechanism. Is the ink refill extending and retracting properly? Try the pen out to make sure the ink is full and flowing correctly.

As an update to the post, I’m also sharing a YouTube video I created. In this video, I show you how to make a cigar pen, but the pen is made out of Tiger Wood. Enjoy!

I hope this tutorial was helpful and what you needed to make your first deer antler pen. Please leave any questions or insights in the comments field. I’m always looking for ways to improve. Also, please consider subscribing to my site. It’s free, and when I add new posts, you will be notified through email. I promise not to share your email.

SAFETY DISCLAIMER: If you decide to attempt this tutorial, you do so at your own risk. Please read my safety disclaimer. I don’t know your skill level, tools, or work environment. Chances are all those factors are different from mine.

Please take some time to learn about this hobby before you jump into it. Watch some videos, read some books, and get some training. Make sure you read the instruction manuals that come with your tools and that you have a clear knowledge of how to operate them safely.

Don’t forget to wear appropriate protective gear—face shield, dust mask, etc. Remove all jewelry or loose clothing that might get caught in the lathe.

Also, these tutorial are intended for adults only. Properly trained and guided, children can do this craft—but only with adult supervision.

Are you starting up a new shop? Want to work safer in your shop? To help you answer these questions I've put together a 2-part checklist -- Home Shop Safety & Tool Checklist.

I will also send you updates of my latest woodworking and DIY projects. You can get all this by subscribing to my free email newsletter.

Thank you I enjoyed your article, pen making is one of those things I would like to do but never get get around to.

Thanks for the comment! It’s a great hobby. Once you get the right equipment and learn how to make the first one, it’s a fairly simple process. The time consuming part comes when others start asking you to make pens for them.