In this post, I will show you how to make a donut stand. This past July, I gave my daughter away in marriage. She assigned me several woodworking projects for the wedding and the donut stand was one of them. You can use this for weddings or other special events in your life. It’s simple to make and only requires a few tools.

Plans, Materials & Recommended Tools

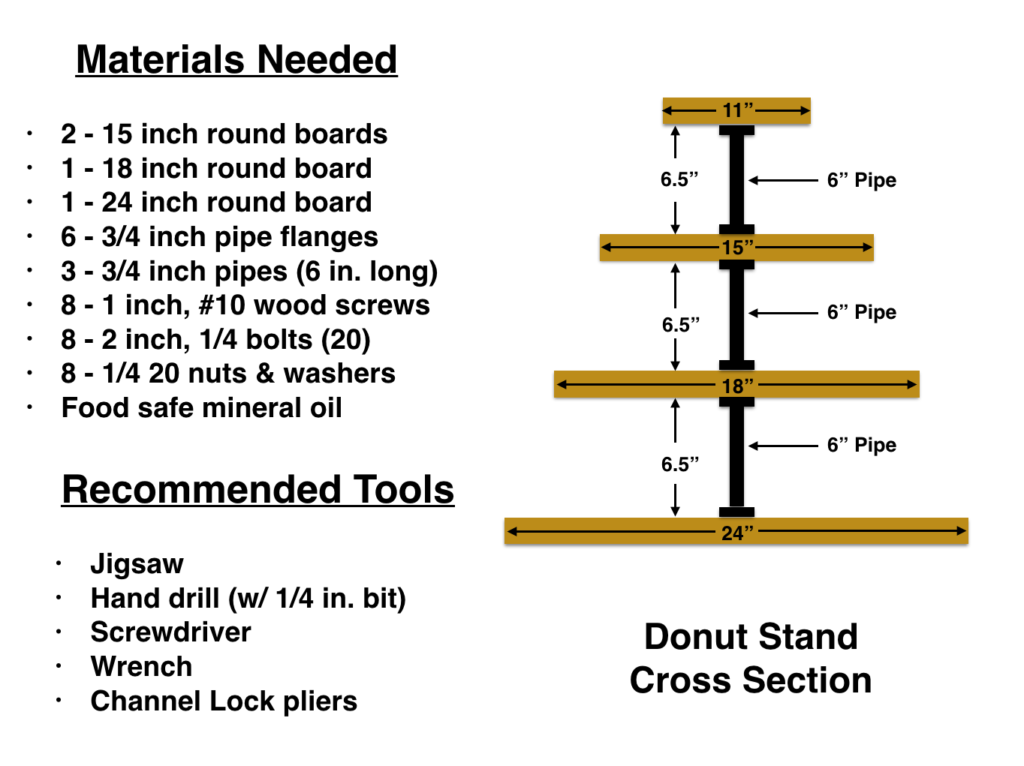

Above are the plans for the donut stand. I bought the boards from Lowes and it’s so convenient that they are pre-cut to circles. The boards are 1 & 1/8 inch thick. Keep in mind that if your boards are thicker or thinner than mine, then you may need to adjust the size of screws and bolts.

Materials you will need

Check out the plans above for a complete list, but the above photos show the boards, the black pipes and screws & bolts. The base board is 24 inches wide. The next board is 18 inches and next board up is 15 inches wide. I used a second 15 inch wide board for the top layer, but I used my jigsaw to cut it down to 11 inches.

Wash Pipes & Flanges

I highly recommend that you wash the pipes and fittings with dish washing fluid and water. The pipes and flanges come with a grease film on them which can be messy. I like to wash these thoroughly and let them dry.

Find the center of each circle.

It’s simple to do. Check out the video below where I explain the technique step-by-step.

Check out the YouTube video above to watch me build the donut stand.

Mark and Dry Fit Flanges

Mark holes for flanges. Drill holes and dry fit the flanges. You may have to make a few adjustments to get all the bolts lined up in each opposing flange.

Don’t forget the top board for the cake. It needs to be a little wider than the cake. I used one of the 15 inch boards and cut it down to 11 inches. You will also need to sand out the saw blade marks and give the edge a curve to match the other boards.

Assembly

Now just start adding the flanges starting with the base board. Add the pipe, then add flange, then bolt boards together (2 center boards). Finish by screwing on the top board. Make sure you get the pipes threaded into the flange properly. They don’t have to be super tight. I just hand tighten them and a couple turns of the channel lock pliers.

Sanding

Now that holes are marked, I used the orbital sander to sand out the pencil marks and get the boards smooth. I started with 120 grit sandpaper, moved to 220 grit and finished with 320 grit.

Finish

I decided to use mineral oil and my own wood butter to finish the boards. It’s simple to apply and it’s food safe.

Above are a couple of photos of the finished donut stand.

I hope you enjoyed my how to make a donut stand tutorial and got a chance to check out the YouTube video.

If you like this tutorial, please consider subscribing. If you subscribe, I will send you a Home Shop Safety List. You’ll find the sign up form below this post.

Are you starting up a new shop? Want to work safer in your shop? To help you answer these questions I've put together a 2-part checklist -- Home Shop Safety & Tool Checklist.

I will also send you updates of my latest woodworking and DIY projects. You can get all this by subscribing to my free email newsletter.